- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- PU Tube

- Polyester-PU Tube

- Polyether-PUR Tube

- Food Grade PU Tube

- Soft PU tube

- PU Anti-static Tube

- PU braided yarn tube

- PUR braided yarn tube

- PU spiral tube

- PU spiral tube (Polyether based)

- PU multi row tube

- PUR multi row tube

- High Temperature and High Pressure PU Tube

- PU Multi Row Spiral Tube

- PU Flame Retardant Tube

- PUR Harness Tube

- PUR Multi-row Spiral Tube

- PA Tube

- Fluororesin Tube

- Polyolefin Series

- Multi-layer Hose Series

- Other Tubes

- Pneumatic Fittings

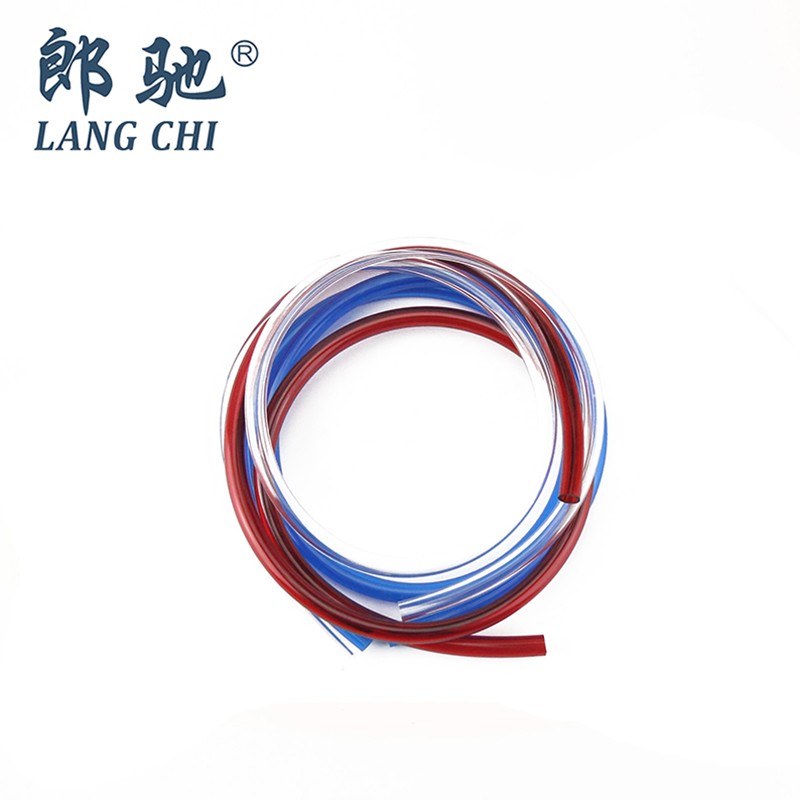

Silicone Tube

LANGCHI is a Silicone Tube Supplier & Manufacturers in China. LANGCHI high-quality silicone rubber tubing with superior flexibility, high-temperature resistance, and excellent chemical resistance. Our silicone tubing comes in a wide range of sizes, wall thicknesses, and colors, customizable for diverse application needs. Whether you require silicone tubing for medical , food processing, chemical, household, or demanding industrial applications, LANGCHI offers reliable, customizable solutions.

Model:LCST

Send Inquiry

Product Name: Silicone Tube

Technical Specifications· Hardness: 70±5

· Tensile Strength: ≥6.5 MPa

· Product Colors: Transparent, white, black, red, yellow, green (custom colors can be produced upon request)

· Temperature Range: -40 to 200℃

· Size Specifications: Diameter ranges from 0.5 to 100 mm

· Surface Performance: Water-repellent, non-stick to many materials, and provides isolation

· Electrical Properties: Minimal changes in performance when exposed to moisture or elevated temperatures. Even when burned in a short circuit, the generated silica remains an insulator, ensuring the continued operation of electrical equipment, making it ideal for manufacturing wires, cables, and connectors.

Product Features: LANGCHI Silicone rubber is a new type of high-performance elastic material with the following characteristics:· High-and-low-Temperature Resistances: Can withstand temperatures up to 200℃, and as low as -40 to -60℃

· Good Biological Stability

· Ability to Withstand Repeated Sterilization

· Excellent Resilience

· Permanent deformation is less than 50% after 48 hours at 200℃

· Dielectric Strength: Breakdown voltage is 20-25 KV/mm

· Ozone, UV, and Radiation Resistance

· Oil Resistance: Specialty silicone rubber exhibits oil-resistant propertiesPerformance Characteristics· Continuous Operating Temperature Range: -60 to 200℃

· Softness: Flexible and adaptable

· Arc and Corona Resistance: Performs excellently under high voltage conditions

· Customizable Specifications: Various specifications can be customized according to customer requirements

· Non-Harmful, Non-Toxic, Odorless: Meets environmental safety standards

· High Pressure Resistance: Suitable for high-pressure applications

· Environmentally friendly

Standard Colors: Black, red, blue, white, gray, green, transparent (other colors available upon request).

Product specification sheet and pressure:

| Model | ID(mm) | OD(mm) | WP/KG | BP/KG | Remarks |

| 1/16*1/8 | 1.6 | 3.2 | 1 | 2 | |

| 1/8*1/4 | 3.2 | 6.25 | 1.5 | 3 | |

| 3/16*5/16 | 4.8 | 7.9 | 3 | 6 | |

| 1/4*3/8 | 6.35 | 9.5 | 3.5 | 7 | |

| 3/8*1/2 | 9.5 | 12.7 | 4 | 8 |

|

Item |

Unit |

Testing standards |

GA-1053 |

GA-1063 |

GA-1073 |

GA-1083 |

|

Hardness |

HA |

GB/T 6031-1998 |

50±2 |

60±2 |

70±2 |

80±2 |

|

Appearance |

Clear |

Clear |

Clear |

Clear |

||

|

Specific gravity(25℃) |

GB/T 533-1991 |

1.16 |

1.19 |

1.22 |

1.23 |

|

|

Degree of plasticity |

GB/T 12828-1991 |

215 |

255 |

305 |

335 |

|

|

Tensile strength |

MPa |

GB/T 528-1998 |

7.5 |

7.0 |

7.0 |

7.0 |

|

Elongation |

% |

GB/T 528-1998 |

450 |

420 |

320 |

200 |

|

Tensile permanent deformation |

% |

GB/T 528-1998 |

7.0 |

7.5 |

7.0 |

6.0 |

|

Tear strength |

kN/m |

GB/T 529-1999 |

21.0 |

20.0 |

20.0 |

20.0 |

|

Resilience |

% |

GB/T 1681-1991 |

53 |

51 |

50 |

50 |

|

Linear shrinkage |

% |

GB/T 17037-2003 |

3.2 |

3.1 |

3.0 |

3.0 |

|

Volume resistivity |

Ω·cm |

GB/T 1692-1992 |

3.5×10 |

3.0×10 |

3.0×10 |

3.0×10 |

|

Breakdown voltage |

kV/mm |

GB/T 1695-2005 |

21 |

21 |

20 |

20 |