- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

- PU Tube

- Polyester-PU Tube

- Polyether-PUR Tube

- Food Grade PU Tube

- Soft PU tube

- PU Anti-static Tube

- PU braided yarn tube

- PUR braided yarn tube

- PU spiral tube

- PU spiral tube (Polyether based)

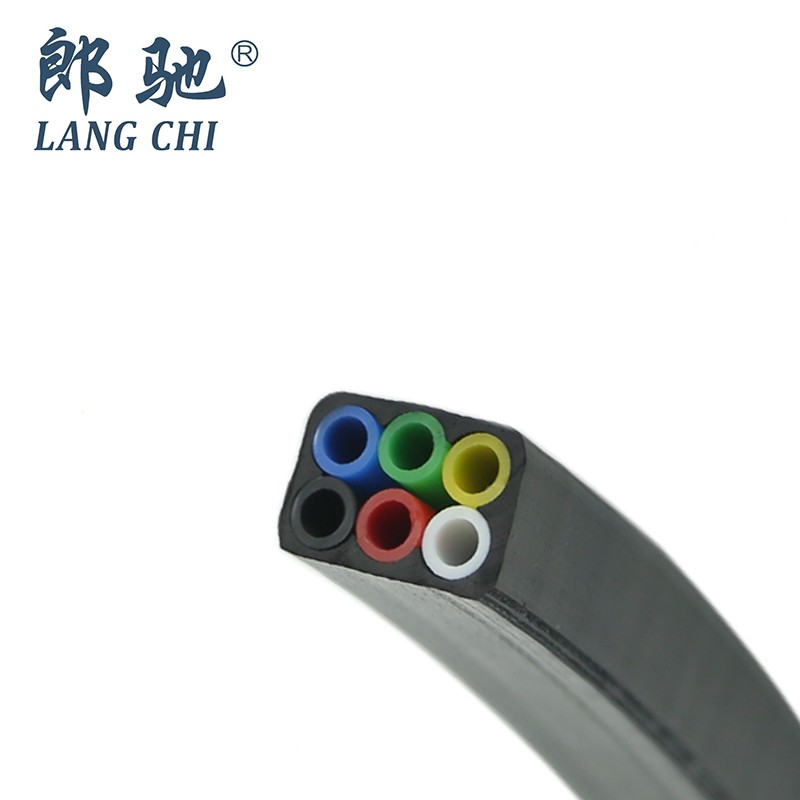

- PU multi row tube

- PUR multi row tube

- High Temperature and High Pressure PU Tube

- PU Multi Row Spiral Tube

- PU Flame Retardant Tube

- PUR Harness Tube

- PUR Multi-row Spiral Tube

- High Temperature Water Tube

- Wear Resistant Tube

- PA Tube

- PA6 Nylon Tube

- PA66 Nylon Tube

- PA12 Nylon Tube

- PA11 Nylon Tube

- Food Grade Nylon Tube

- Soft Nylon Tube

- Anti Static Nylon Tube

- Nylon Multi-core Hose

- PA Double Layer Flame Resistant Tube

- Fire Detection Tube

- Bio-based Nylon Tube

- Nylon Single Layer Flame Retardant Tube

- Nylon Double Layer Flame Retardant Tube

- Food Grade Nylon Tube (Precision)

- Nylon Spiral Tube

- Fluororesin Tube

- Polyolefin Series

- Multi-layer Hose Series

- Other Tubes

- Pneumatic Fittings

PUR tube(Ether-Based Polyurethane)

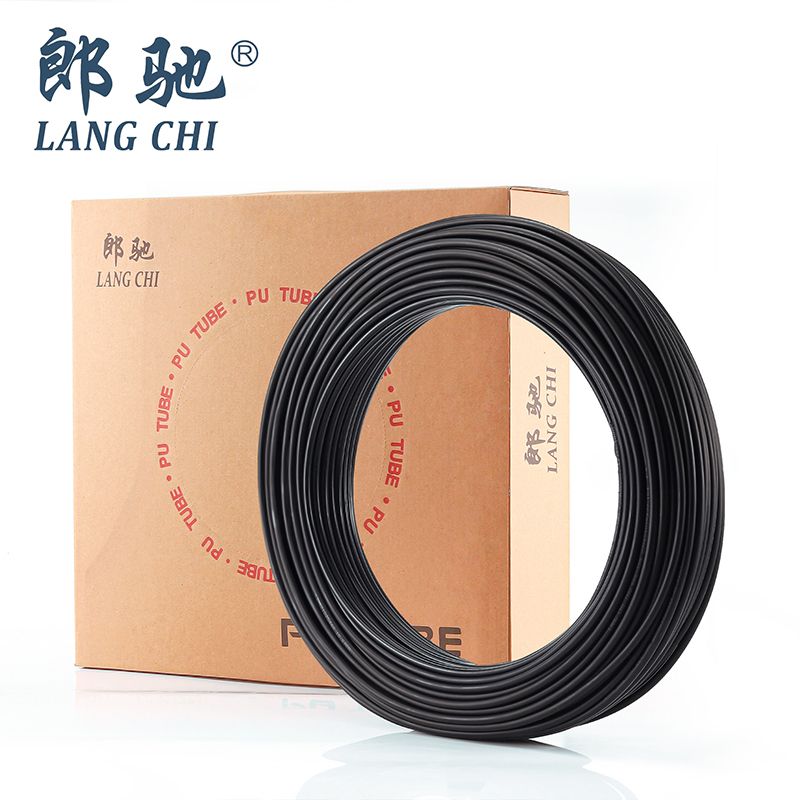

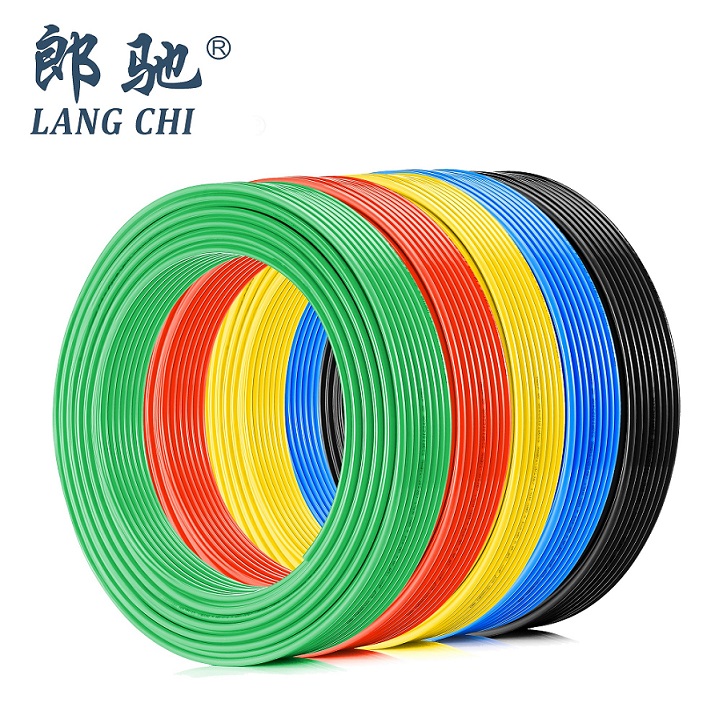

LANGCHI is a professional PU tube manufacturer and supplier in China. These colored PUR tubes use weather resistant pigments with standard and bright colors, but they don't contain softeners and have passed RoHS and CE certificates.

Model:LCTU

Send Inquiry

Product Introduction

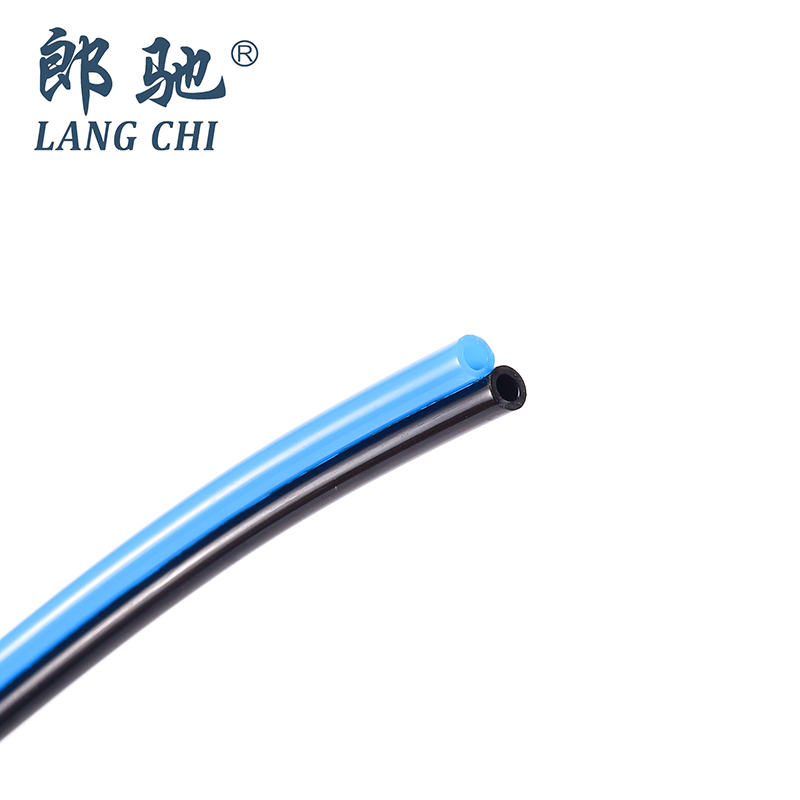

Product Name: PUR Tube

Material: Polyether polyurethane

Fluid: Air, water

Working temperature: -40 ℃~+70 ℃(Air), 0 ℃~+40 ℃(Water)

Maximum working pressure (at 20 ℃): 0.8Mpa

Hardness: 85A-98A

Length:

200m/roll (OD less than 6mm)

100m/roll(OD more than 8mm)

Tolerance:

OD4-12mm, tolerance is ± 0.1mm

OD14-16mm, tolerance is ± 0.15mm

Packaging: box, spool

Product Parameter

| Model |

OD×ID (mm) |

Working temperature (℃) |

Maximum working pressure (Mpa ) |

Minimum bending radius (mm) |

||

| 20℃ | 40℃ | 60℃ | ||||

| LCTU0212 | 2×1.2 |

-40℃~+70℃ (for Air) '0℃~+40℃ (for Water) |

Air 0.8 Water 0.6 |

Air 0.65 Water 0.5 |

Air 0.5 Water 0.4 |

4 |

| LCTU0425 | 4×2.5 | 10 | ||||

| LCTU0604 | 6×4 | 15 | ||||

| LCTU0805 | 8×5 | 20 | ||||

| LCTU1065 | 10×6.5 | 27 | ||||

| LCTU1208 | 12×8 | 35 | ||||

| LCTU1410 | 14×10 | 40 | ||||

| LCTU1612 | 16×12 | 45 | ||||

| LCTU 1/8" | 3.18×2 | 10 | ||||

| LCTU 3/16" | 4.76×3.18 | 15 | ||||

| LCTU 1/4" | 6.35×4.23 | 23 | ||||

| LCTU 3/8" | 9.53×6.35 | 27 | ||||

| LCTU 1/2" | 12.7×8.46 | 35 | ||||

Product Feature And Application

Feature:

Good mechanical properties, tensile strength, pressure resistance, wear resistance, UV resistance, bending resistance, good hydrolysis resistance, low temperature resistance, good low temperature flexibility, more chemical resistance, longer service life.

Application:

1.Pneumatic: Pneumatic actuator, pneumatic valve, pneumatic tool, pneumatic sensor, pneumatic transfer system, pneumatic spray painting system, pneumatic grips, pneumatic filter and pressure adjustor, pneumatic piping, pneumatic cooling system.

2.Automation: Pneumatic cylinder, automated grip, robot arm, spraying equipment, transfer system, automated assembly line, pneumatic filter and pressure adjustor, automated testing equipment, pneumatic raw material feeding equipment, packaging equipment.

3.Rapid Circulation: Pneumatic transmission system, automated assembly line, spraying system, material transfer system, pneumatic grip, pneumatic raw material feeding equipment, robot system, fast mold changing system, pneumatic cooling system, experiment and testing system.

4.Automobile Production: Fuel conveying system, cooling system, pneumatic system, braking system, air conditioning, exhaust system, window control, power steering system, oil pressure system, decor and sealing.