- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

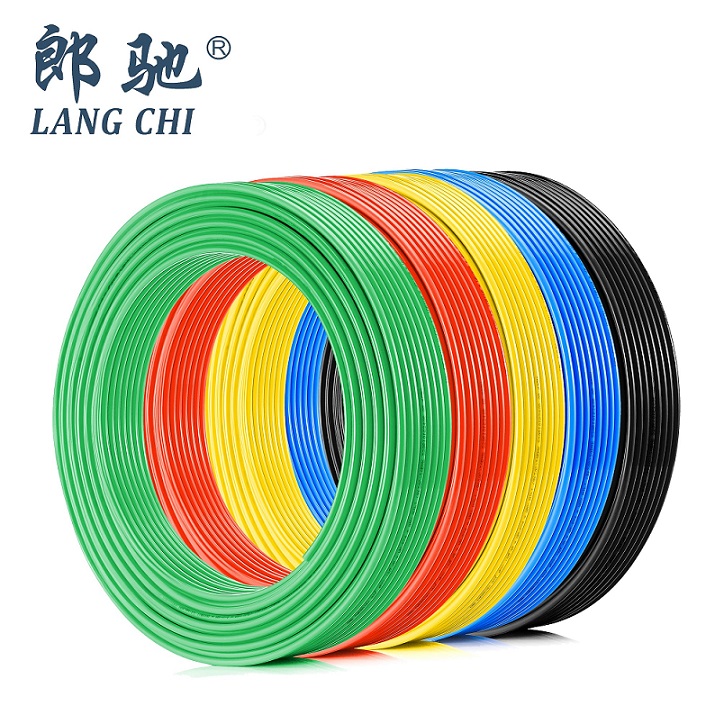

What do pu tubes need to pay attention to when transporting

2024-12-16

When transporting PU (Polyurethane) tubes, there are several factors that need to be taken into account to ensure their safety and integrity. Here are the key considerations:

1. Proper Packaging

- Protection from Physical Damage: PU tubes are flexible and can easily get damaged if not properly packaged. They should be coiled or packed in boxes that prevent them from being crushed or scratched.

- Avoid Sharp Objects: Ensure that the tubes are not in contact with sharp edges, as this could cause punctures or tears.

- Use of Protective Sleeves or Wrapping: To protect the tubes from dust, moisture, and contaminants, consider using plastic sleeves or stretch film to wrap them securely.

2. Temperature Control

- Avoid Extreme Temperatures: PU tubes can become brittle or soft if exposed to extreme heat or cold. It is important to avoid exposing them to direct sunlight, or extremely hot or cold environments, especially during storage and transport.

- Storage at Room Temperature: Ideally, store and transport PU tubes at a temperature between 15°C and 30°C (59°F to 86°F).

3. Humidity Control

- Keep Dry: PU tubes should be kept dry during transportation. Prolonged exposure to moisture can degrade the material, leading to swelling, softening, or loss of mechanical properties.

- Avoid Contact with Water: Make sure that the tubes are not exposed to rain or humidity. This is especially important for longer transport durations.

4. Avoid Overloading

- Prevent Crushing: When loading PU tubes onto trucks or containers, avoid overloading or stacking heavy objects on top of them. Overloading can cause the tubes to deform or become crushed.

- Correct Positioning: Ensure the tubes are loaded in such a way that they are not subjected to unnecessary stress or weight. They should lie flat or be secured to avoid movement during transit.

5. Handling

- Gentle Handling: PU tubes are flexible but should still be handled carefully. Avoid dropping, throwing, or dragging the tubes, as these actions could cause dents or stress marks on the material.

- Use Proper Equipment: For large shipments, use forklifts or hoists with appropriate lifting straps to handle the tubes without causing deformation.

6. Labeling

- Clear Labeling: Mark the packaging with handling instructions, such as "Fragile" or "Keep Dry," to ensure that anyone handling the shipment is aware of the care required for PU tubes.

- Identification of Contents: If transporting multiple items, label each package with clear identification so that the tubes are handled correctly.

7. Regulatory Compliance

- Check Local Regulations: If transporting PU tubes across borders or in large quantities, ensure that you are compliant with local regulations regarding packaging, transport, and safety.

8. Inspection Before Transport

- Visual Inspection: Before shipping, visually inspect the PU tubes for any defects, such as cracks, tears, or other visible damage, and ensure they are packaged securely.

- Inventory Check: Ensure that the correct quantity and type of PU tubes are ready for transport, and confirm that all packaging and documentation are complete.

By following these precautions, the integrity of PU tubes can be maintained during transport, ensuring they arrive at their destination in optimal condition.

LANG CHI is a professional PU tube manufacturer and supplier in China, as well as a high-tech enterprise integrating research and development, production, sales, and international trade. Visit our website at www.langchi-pneumatic.com to learn more about our products. For inquiries, you can reach us at nblangchi@nb-lc.cn.